The Greatest Guide To Premier Aluminum Llc

The Greatest Guide To Premier Aluminum Llc

Blog Article

Getting The Premier Aluminum Llc To Work

Table of ContentsThe 8-Minute Rule for Premier Aluminum LlcThe 10-Second Trick For Premier Aluminum LlcSome Known Details About Premier Aluminum Llc Premier Aluminum Llc - An Overview

(https://www.reverbnation.com/premieraluminumllc)Using reduced expense and unqualified vendors can cause high quality problems, and wasted time and money in the long run. To assist you through the process, here are some things to consider when selecting the ideal steel spreading distributor.

A firm that only utilizes the financial investment spreading process will attempt to sell you on why that process is best for your application (Casting Foundry). What if using the sand spreading procedure is best for you and your demands? Instead, try to find a vendor that uses a variety of casting procedures so the best alternative for YOU is chosen

If collaborating with a single source for all of your casting requires is very important to you, the distributor requires to be diverse in its capacities. When integrated with other incorporated capabilities, this can assist simplify and press the supply base. When picking the appropriate casting vendor, cautious factor to consider ought to be offered to quality, service, and rate.

The Main Principles Of Premier Aluminum Llc

Customers significantly pick casting providers who have machining abilities. If the casting supplier discovers a concern throughout machining, the issue is fixed faster with no dispute over whose mistake it is.

Issue or no, integrated machining streamlines the supply chain and minimizes managing time and shipping expense before the product makes it to the customer. What do you need from your spreading vendor? Are you seeking somebody to just supply a metal component to your doorstep or do you need more? If you do not have internal metallurgy competence, confirm that the supplier can give assistance in picking the appropriate alloy based on your details application.

Some factories are limited or specialized. Make sure the supplier can meet all your material or alloy needs to eliminate the requirement for numerous suppliers.

The Best Guide To Premier Aluminum Llc

Study the supplier's site. Talk with a sales rep or business associate. Ask a great deal of concerns. Visit their center. Obtain an understanding of what they can do for you and if you can see on your own constructing a strong, mutual relationship with them.

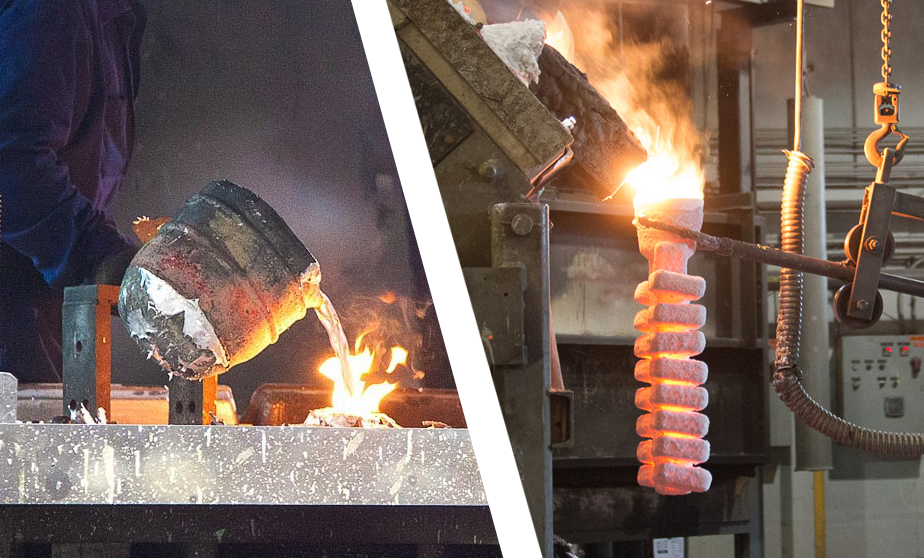

Light weight aluminum is additionally light-weight and has great rust resistance, making it excellent for applications where weight and longevity are very important factors. Furthermore, aluminum spreading is a cost-effective approach of manufacturing, as it requires much less energy and sources than other approaches. Iron spreading, on the other hand, entails pouring molten iron right into a mold to develop a preferred form.

Some Ideas on Premier Aluminum Llc You Should Know

Iron casting is also able to hold up against high temperatures, making it ideal for usage in applications such as engine parts and industrial equipment. However, iron casting can be much more pricey than aluminum spreading because of the greater price of resources and the power called for to melt the iron. When deciding in between aluminum spreading and iron casting, it is essential to consider the details demands of the application.

In final thought, both light weight aluminum casting and iron casting have their very own distinct advantages and downsides. There are three sub-processes that fall under the category of die spreading: gravity pass away casting (or permanent mold spreading), low-pressure die spreading and high-pressure die casting. To get to the finished item, there are three primary alloys used as die spreading material to choose from: zinc, light weight aluminum and magnesium. Report this page